Optional equipment, in-line or stand-alone

At Pontum, we understand that a packaging line requires more than just fillers. To enhance the efficiency and versatility of your operation, we offer a range of optional modular equipment that seamlessly integrates into your existing setup, helping you streamline your production process and ensure a professional, high-quality final product.

Infeed table makes the filling process flow easily feeding bottles or cans into the filler, adjusting the speed as needed. It accommodates around 60 bottles.

- Robust stainless steel design

- Adjustable speed

- Buffer circa 60 bottles

- On wheels

Our wrap-around labellers are designed to handle various bottle and can sizes, applying labels with accuracy and speed. Most often they are placed between the infeed table and the filler. Whether you need front, back, or wrap-around labels, our labellers ensure consistent application, making your packaging as professional as the beer inside. The labellers can be equipped with an integrated date printer.

- Wrap around labelling

- Label width 20-120mm

- Label length 20-300mm

- With printer

- On wheels

Rinsing bottles prior to filling can be done with Pontum’s rinsers. Depending on your needs we can offer you a semi-automatic or a fully automatic inline rinser.

- Semi automatic rinser

- Loading with gripper 24 bottles/grip

- Adjustable bottle sizes

- On wheels

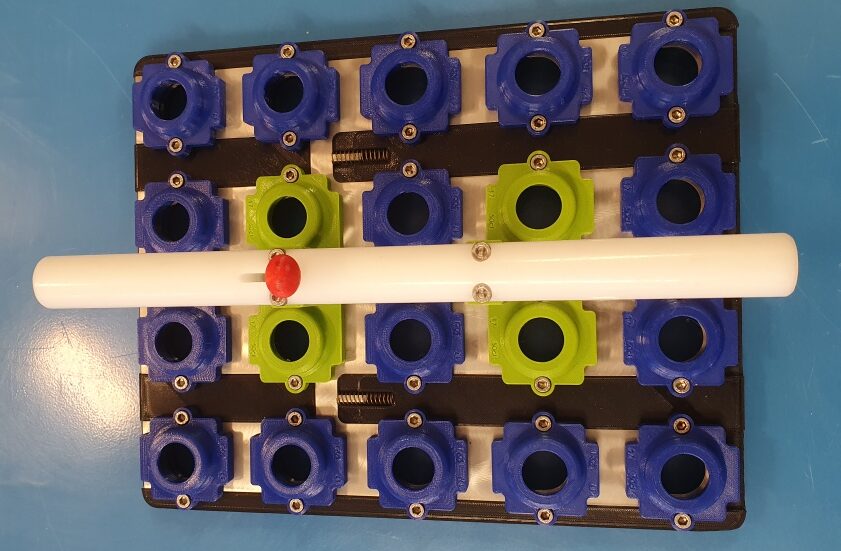

Our grippers is another example of our time-saving design. Those are custom made according to the pattern of your box and the size of your bottles.

- Time saving

- User friendly

- Indispensable

A video of a Gripper at work