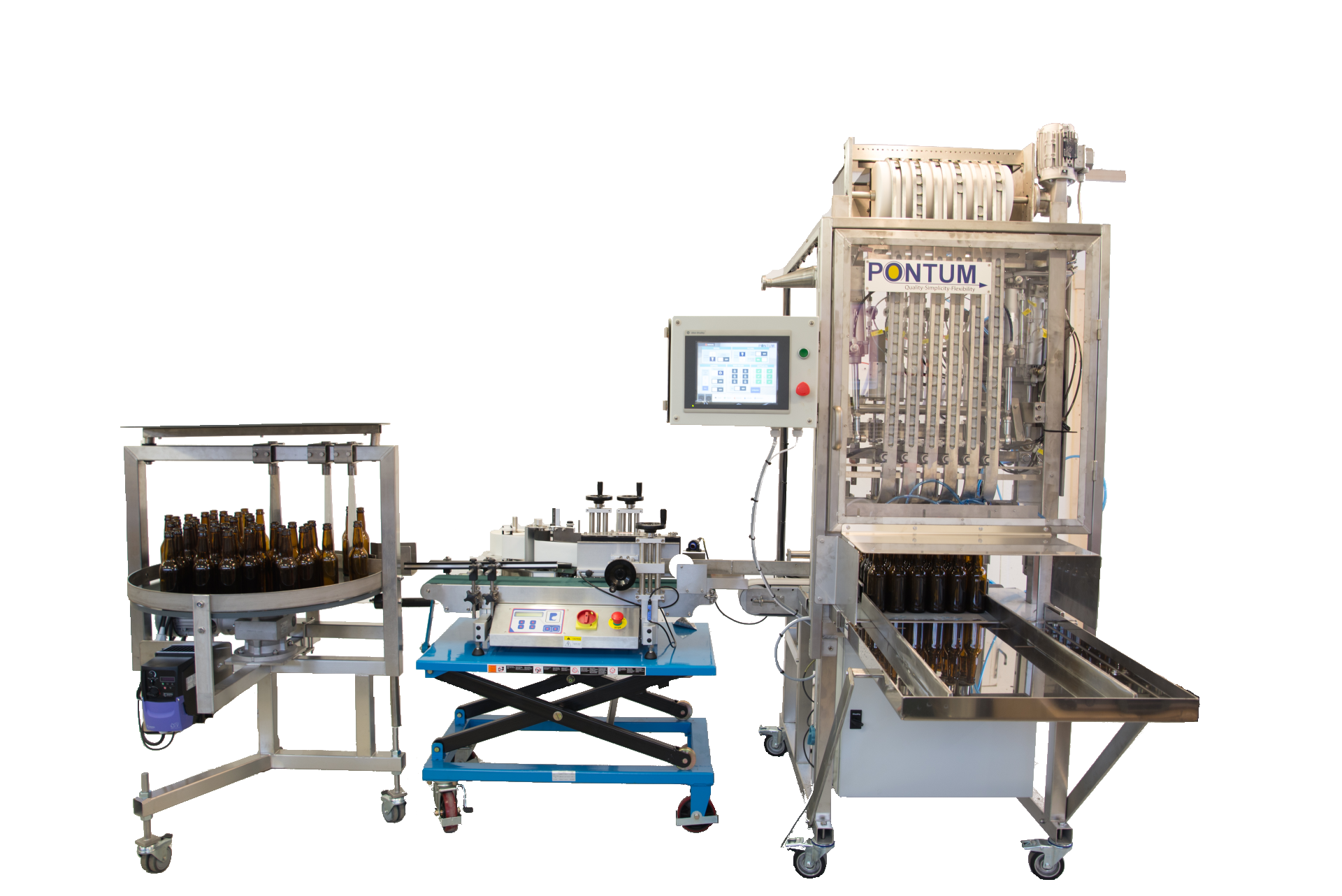

Quality – Simplicity – Flexibility

Pontum products

Equipment for filling of bottles and/or cans, built by modular units. Unique machines that can be extended. Build your line designed after your specfic needs today and add on in the future when needed.

Filler and Capper FK 1-6. Our most popular machine.

- Filling machine with 6 heads

- Flexible bottle sizes diameter 60-90mm, height 180-300mm

- 1800 bottles/hour

- On wheels

- Compact

- Integrated output table

- 100% efficient oxygen pre-evacuation

Filler and Capper FK 1-2

- Long tube filling 2-heads

- Flexible bottle sizes diameter 60-90mm, height 180-300mm

- 600 bottles/hour

- Expandable to 6-heads

- On wheels

- Compact

- Integrated output table

- 100% efficient oxygen pre-evacuation

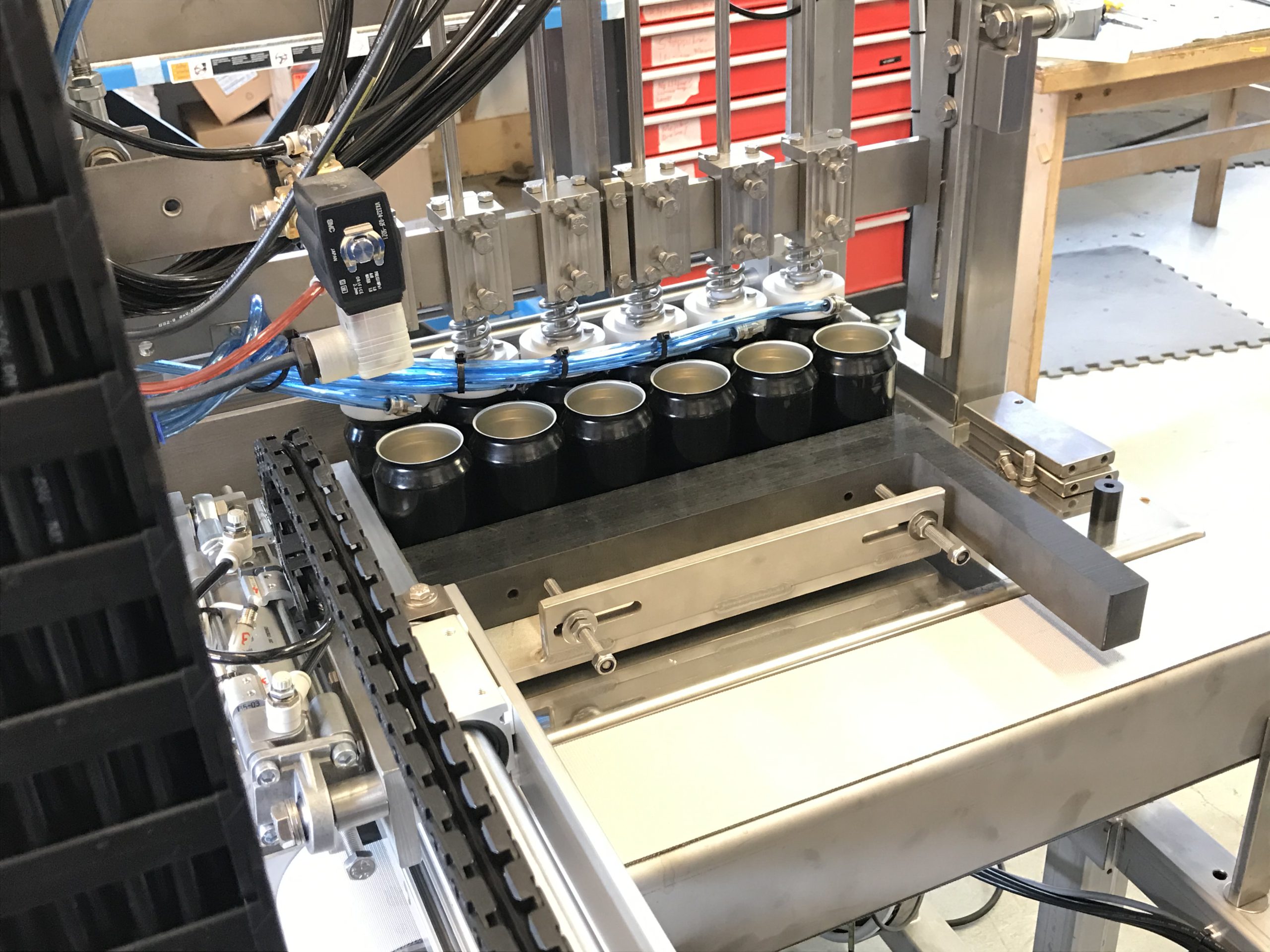

Canning unit

Connected to bottling machine in 30 minutes.

First in both gravity- and counter pressure filling.

Counter pressure filling up to 2 bar.

Cans, diameter: Standard and Sleek.

Cans, height: 100-200mm, easily adjustable by client.

Capacity: 1200 Cans per hour.

Feed out buffer: Approx. 60 cans.

Weight unit with sort out and feedback.

Seamer: Best on the market, stable and servo controlled.

Oxygen and foam as with bottles.

Most compact equipment on the market.

Labelling machine

- Wrap around labelling

- Label width 20-120mm

- Label length 20-300mm

- With printer

- On wheels.

Feeding table

- Robust stainless steel design

- Adjustable speed

- Buffer circa 60 bottles

- On wheels

- Integrated with FK and labelling for start and stop.

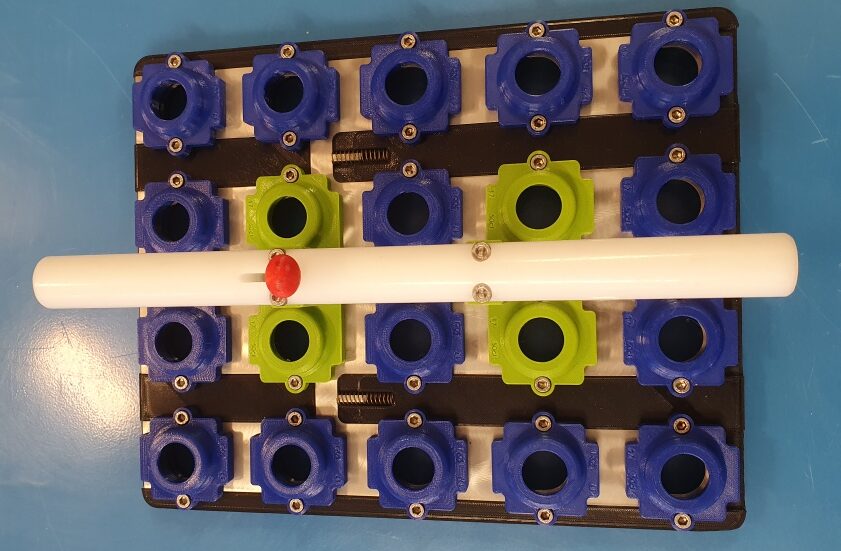

Semi automatic rinser

- Semi automatic rinser

- Loading with gripper 24 bottles/grip

- Adjustable bottle sizes

- On wheels

Gripper for 50cl

- Time saving

- User friendly

- Indispensable

Gripper for 33cl

- Time saving

- User friendly

- Indispensable

A typical Pontum filling line