Can-fillers Technical Information

Cans have become more and more popular among beer-lovers today.

Pontum machines have the unique possibility to extend our bottle fillers with a canning unit, as well as can-only-fillers. Other modules, like the infeed table, automatic rinser and labeller handle both bottle and cans.

Specifications:

-Long tube filling in rows

-Individual control of levels in each can. Easily adjusted on the HMI

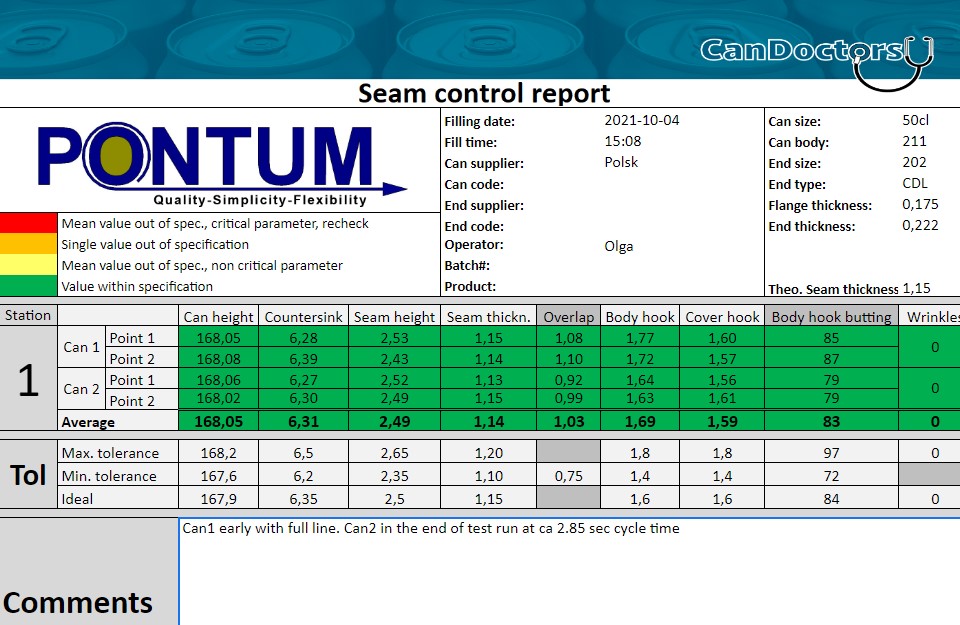

-Unique “best in business” seamer with servo control. Easily adjusted to 100% precision of specifications by supplier and Can Experts

-Cans sizes: STD 66mm or Sleek

-Cans, height: 100– 200 mm, easily adjusted

-Capacity: 1200 cans / hour

-Pressure drop filling

-Counter pressure filling

-Date printing on bottom

-Integrated with new and old machines

Oxygen

-Integrated CO2 tubes in the filling tubes, start blowing CO2 when the filling tubes descend into the cans. Time for evacuation is easily adjustable on HMI

-Adding of CO2 direct after filling and additional before lid application

-Oxygen levels down to 4 ppb

Foam

-With counter pressure filling pressure is adjustable between 0 – 2 bar with filling and decompression adjustable as with bottles.

-With pressure drop filling CO2 jet for additional foaming. Adjustable on HMI.

Lids

-Easy refill of one full tube at the time

-Easily adjusted lid dispenser

Weight unit

-Easily adjusted MIN and MAX values in gram, on HMI

-Out sorting of out-of-range cans

-Feedback of weight for all cans

COMING SOON

-CAN GRIPR

-LOW COST DEPALLETIZER

-CU LIGHT WITH LIGHT PRICE